Sterile filling of small batches –

flexible filling and closing machine

Aseptic filling of RTU Vials, Syringes and Cartridges

Filling in research, development and production

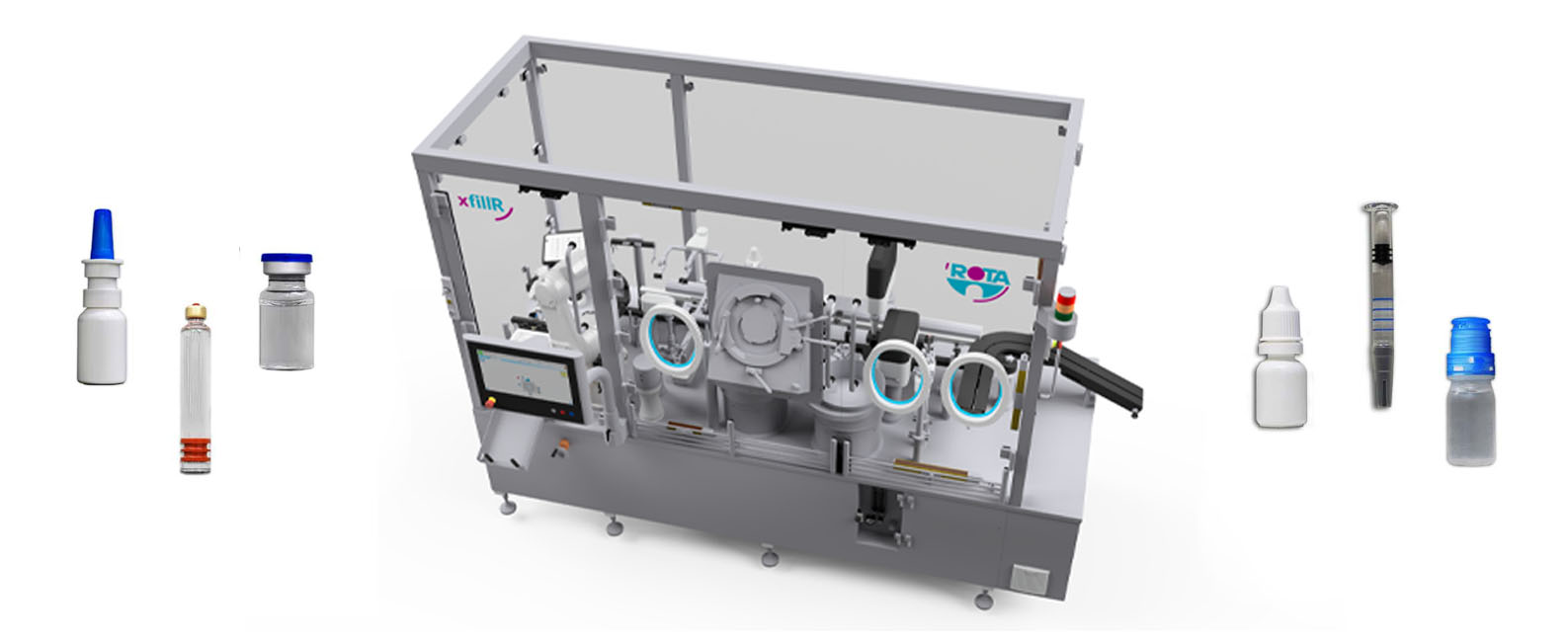

As a universal filling machine the xfillR is the perfect solution for use in R&D and manufacture of batches for clinical studies in the pharmaceutical industry. Often, especially in the development phase of medicine, the dosage form has not yet been determined. With the xfillR, you keep all your options open.

In the biotech industry, too, the xfillR is the ideal system for aseptic processing of small or very small batches. Personalized, highly effective and expensive medicine deserves individual and particularly gentle treatment under safe conditions.

A unique feature of this extremely compact filling machine is its small footprint. It can even be installed against a wall and operated from one side. This makes the xfillR a cost-saving addition to any laboratory which can be expanded at a later date.

On the mandate for maximum flexibility and modularity, all cylindrical containers can be transported, filled and sealed precisely and safely.

German technology for our health – made by ROTA

FLEXIBILITY

The xfillR processes batch sizes as small as 1 object with the highest precision and the required sterility.

The xfillR offers the unique possibility of processing a wide variety of cylindrical objects with just one multipurpose machine:

- Vials

- Syringes

- Eye droppers

- Nasal sprays

- Cartridges

- Micro-tubes

- in nests, trays or in bulk

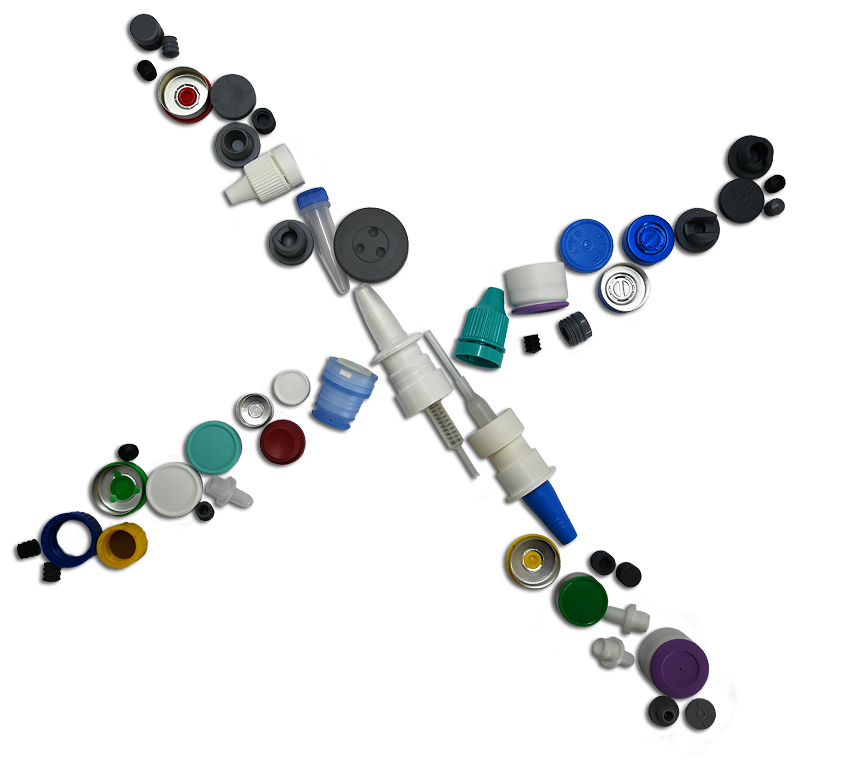

For closing the objects, the xfillR can also handle different types of closures:

- Stoppers

- Droppers

- Tear-off or flip-off caps

- Screw caps

- Spray pumps

MODULARITY

Clever use of space: With a length of only 2.40 m, the xfillR offers sufficient freedom for extensions by adding individual processing stations.

- Thanks to the integrated servo control system and the modular software concept, modules can also be installed at a later date

- Upstream connection of an unpacking station and/or also of a rapid decontamination airlock

- Downstream connection to other processing systems such as freeze dryer, conveyor belt, tray loader or re-nester

„ZERO-REJECT“ SYSTEM

Especially in the cost-intensive development phase of pharmaceuticals or in the production of personalized medicine, high production efficiency is paramount for high availability and process reliability.The xfillR with its zero reject system achieves maximum batch yield with up to 1.800 objects per hour:

- At the start of production, the pump tubes are vented without product loss, and the fill object does not leave the filling station until the target fill volume has been reached.

- Each individual object is checked during the production run (100%-IPC)

- Re-Fill

The integrated load cell at the filling station ensures the necessary filling accuracy; underfilled containers are topped up immediately. - Re-Stoppering & Re-Capping

A detected missing stopper or cap leads to an immediate automatic re-stoppering or re-capping cycle. - Re-Torquing of screw caps

If the measured torque is below the set tolerance, the cap is immediately re-torqued.

The zero reject system ensures that valuable product yield is maximised. Thanks to maximum precision, the xfillR with its zero reject system guarantees the highest possible process and product quality.

EASE OF USE

Simple, fast handling is essential when processing a variety of objects. The innovative xfillR ensures that, while complying with current applicable guidelines and standards, user-friendliness is paramount.

- The few format parts can be changed quickly and without tools

- Ergonomic access; operator access required from one side only

- Intuitive, guided operation of the machine through the large screen user-friendly operator panel